Understanding SCR Systems: From Environmental Compliance to Cost-Saving Choices

Introduction

This article examines the Selective Catalytic Reduction (SCR) system, widely used in modern diesel technology to meet high environmental standards starting from EURO-4. It provides a detailed description of how this system works, the role of the AdBlue reagent (also known as DEF, and UREA), as well as common causes of malfunctions and the feasibility of disabling the SCR system, including its advantages and available methods for solving problems faced by owners of trucks, buses, agricultural, and construction equipment.

Environmental Standards and the SCR System

The EURO-4 emission standard has governed vehicle design throughout Europe since its 2004 implementation, while corresponding Tier 3 and Tier 4 regulations were phased in for heavy-duty trucks, buses, and non-road machinery in the United States between 2010 and 2014. All regimes seek to curtail the release of regulated pollutants by imposing stringent thresholds on hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) in the combustion by-products. Original equipment manufacturers, to comply, have adopted a suite of proven control technologies, notably diesel particulate filters (DPF) for soot control, exhaust gas recirculation (EGR) for NOx mitigation, and selective catalytic reduction (SCR) for simultaneous reduction of NOx and ammonium aerosol formation.

The SCR system, unlike EGR, does not affect directly the engine’s operation but plays a key role in purifying exhaust gases. Despite its effectiveness, it often becomes a source of difficulties for truck owners. In the following sections, we will examine in detail why truck owners consider disabling AdBlue (urea), as well as evaluate the prospects of such actions.

What is AdBlue and How Does the SCR System Work?

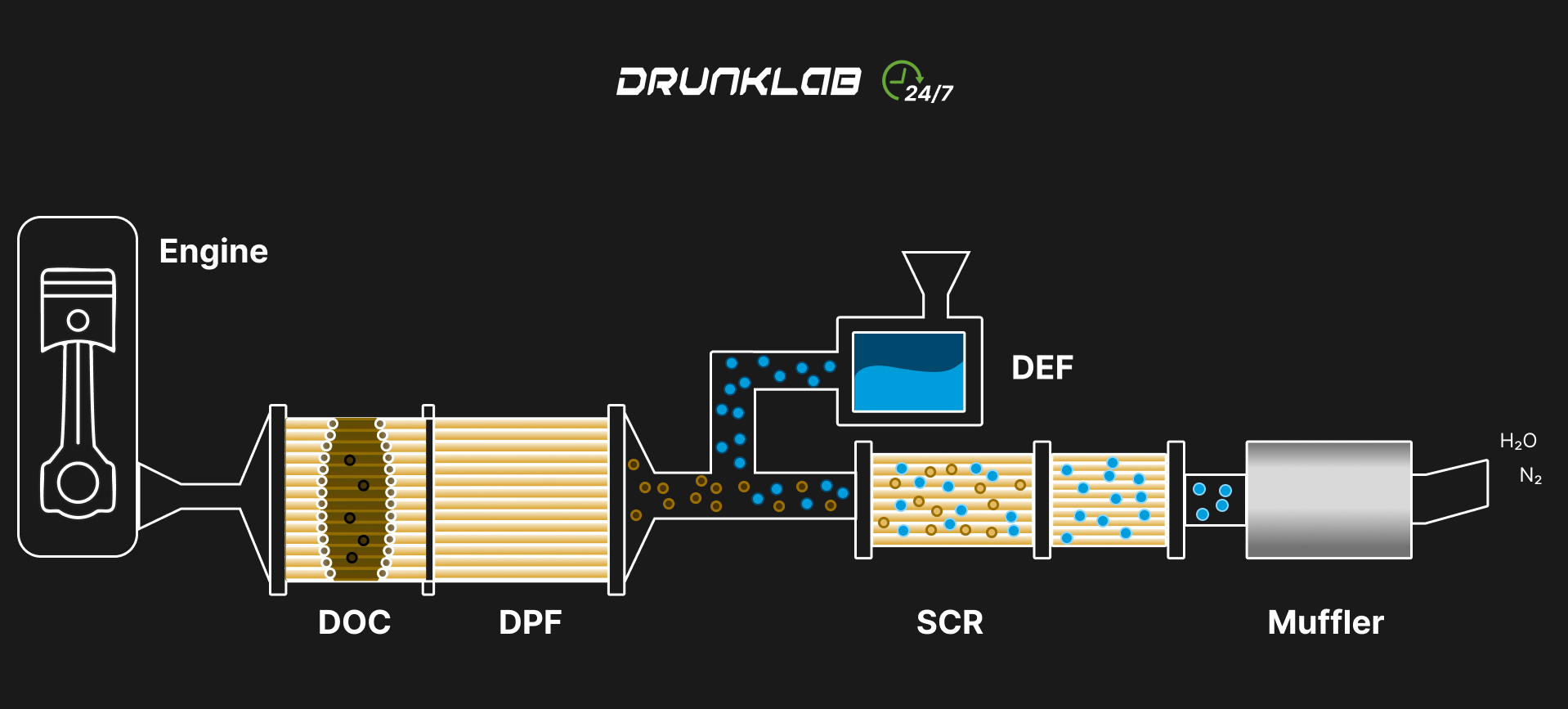

AdBlue is an aqueous solution of urea that is injected directly into the exhaust gas stream in the muffler’s exhaust tract. As a result of a chemical reaction with nitrogen oxides, harmless substances are formed: pure nitrogen and water (see Figure 1).

SCR (Selective Catalytic Reduction) is a device that uses a urea-based reagent known as AdBlue (or DEF, UREA) to control the exhaust system and significantly reduce emissions of nitrogen monoxide (NOx) into the atmosphere.

General Diagram of a Truck’s Environmental Systems

(Figure 1)

The Nitrogen Oxides Urea neutralization technology is used by most major manufacturers of trucks and agricultural equipment. The urea solution in water is a strictly standardized product (according to DIN 70070 and ISO 22241) and is produced only under license, as even minor impurities can damage the expensive SCR equipment.

SCR System Operation Process

The AdBlue solution is introduced into the catalytic converter chamber, where its vapor mixes with the exhaust gases, thereby reducing the emission of harmful substances (NOx). However, the SCR system is effective only when the engine reaches the required operating temperature (360-450 °C or 680–842°F), before the NOx reduction process begins. The exhaust gas temperature sensor continuously sends data about this temperature to the electronic control unit (ECU), which regulates the supply of AdBlue.

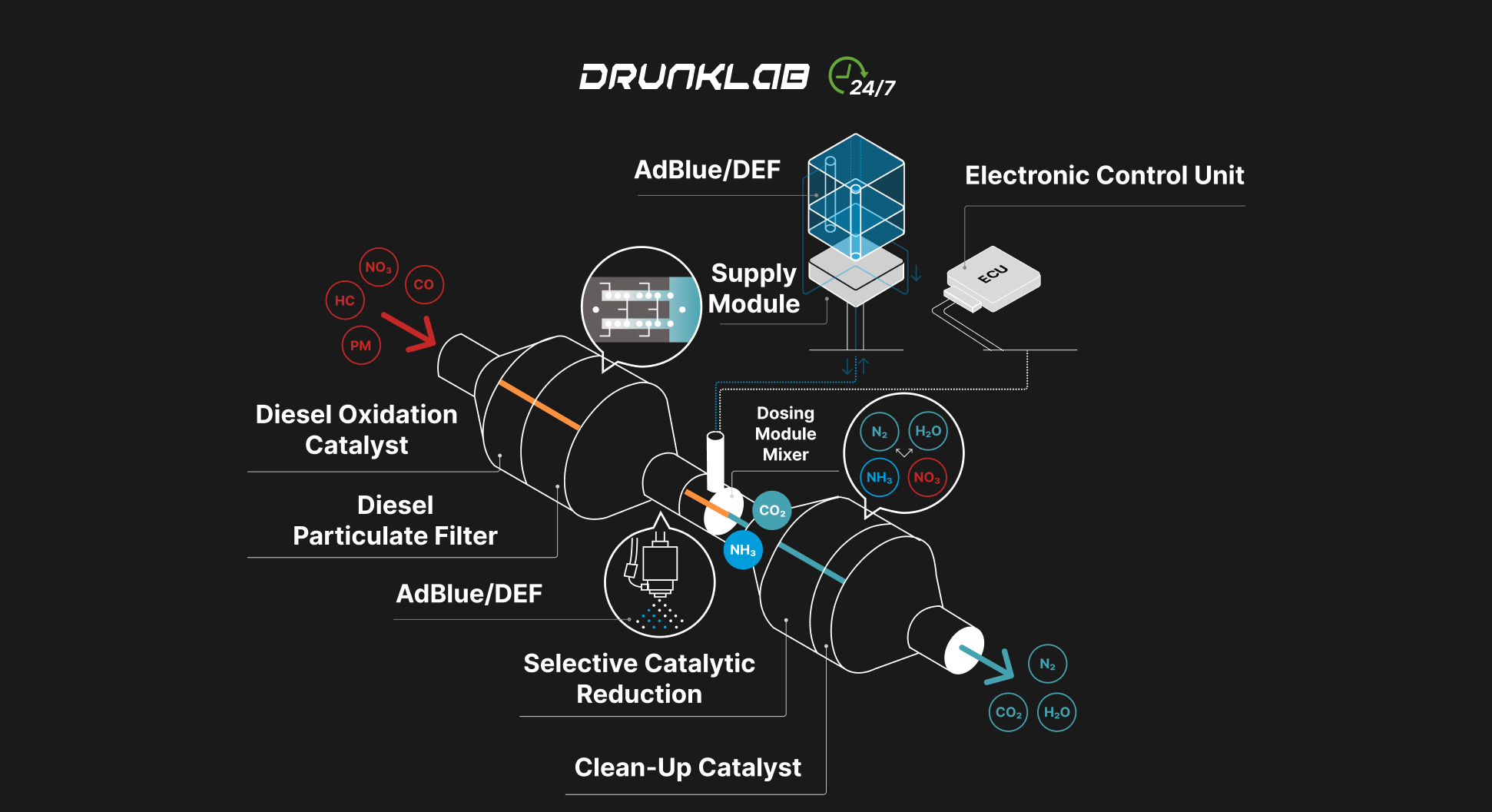

Schematic Diagram of the SCR System

(Figure 2)

The core of the SCR catalytic converter is usually made of ceramics (titanium oxide) and coated with oxides of various metals, such as tungsten, vanadium, molybdenum, as well as other precious or rare metals. To perform the reduction reaction, the SCR system requires an additional reagent. This role can be played by anhydrous ammonia, aqueous ammonia, or the most common urea solution AdBlue.

Trucks are equipped with a special stainless steel tank with a blue cap for AdBlue, with a capacity of 20-30 liters (5–8 gallons). This is usually enough for a full fuel tank refill. The AdBlue tank volume is almost always proportional to the fuel tank volume. Urea consumption is approximately 4-8% of fuel consumption. Through the pump module, the DEF fluid is pumped into the dosing device, from where it is injected under 5 bar pressure into the catalytic converter heated to 200°C (392°F). After that, hydrolysis occurs with the formation of ammonia, which then enters the reduction reaction, forming initial nitrogen and water.

Dosing and AdBlue Storage Conditions

The amount of injected urea is regulated and calculated by the dosing unit in real time. This is influenced by several factors:

- Temperature of the converter and ambient environment.

- Current engine load.

- Crankshaft rotation speed.

It is important to note that during engine idle operation, urea injection does not occur, but pressure in the system is maintained. This ensures the system’s readiness for immediate operation when the engine mode changes.

Attention: Special AdBlue Storage Conditions

AdBlue is very sensitive to storage conditions and temperature fluctuations. The optimal storage period is no more than 36 months at temperatures from 0°C to 10°C (32–50°F). At temperatures above 25°C (77°F), the storage period is halved. Although the product does not lose its properties after a single freeze or thaw, prolonged violation of the temperature regime leads to loss of its effectiveness. AdBlue tanks on vehicles usually maintain temperature, as they are equipped with autonomous heaters, which prevent freezing even during prolonged parking at -40°C (-40°F). The dosing device and supply unit also have heating to ensure uninterrupted operation.

Precautions: AdBlue causes accelerated corrosion of iron, aluminum, and copper. If the liquid gets on these surfaces, it should be immediately washed off with water and wiped dry. It is also recommended to avoid contact with skin.

Precautions: AdBlue causes accelerated corrosion of iron, aluminum, and copper. If the liquid gets on these surfaces, it should be immediately washed off with water and wiped dry. It is also recommended to avoid contact with skin.

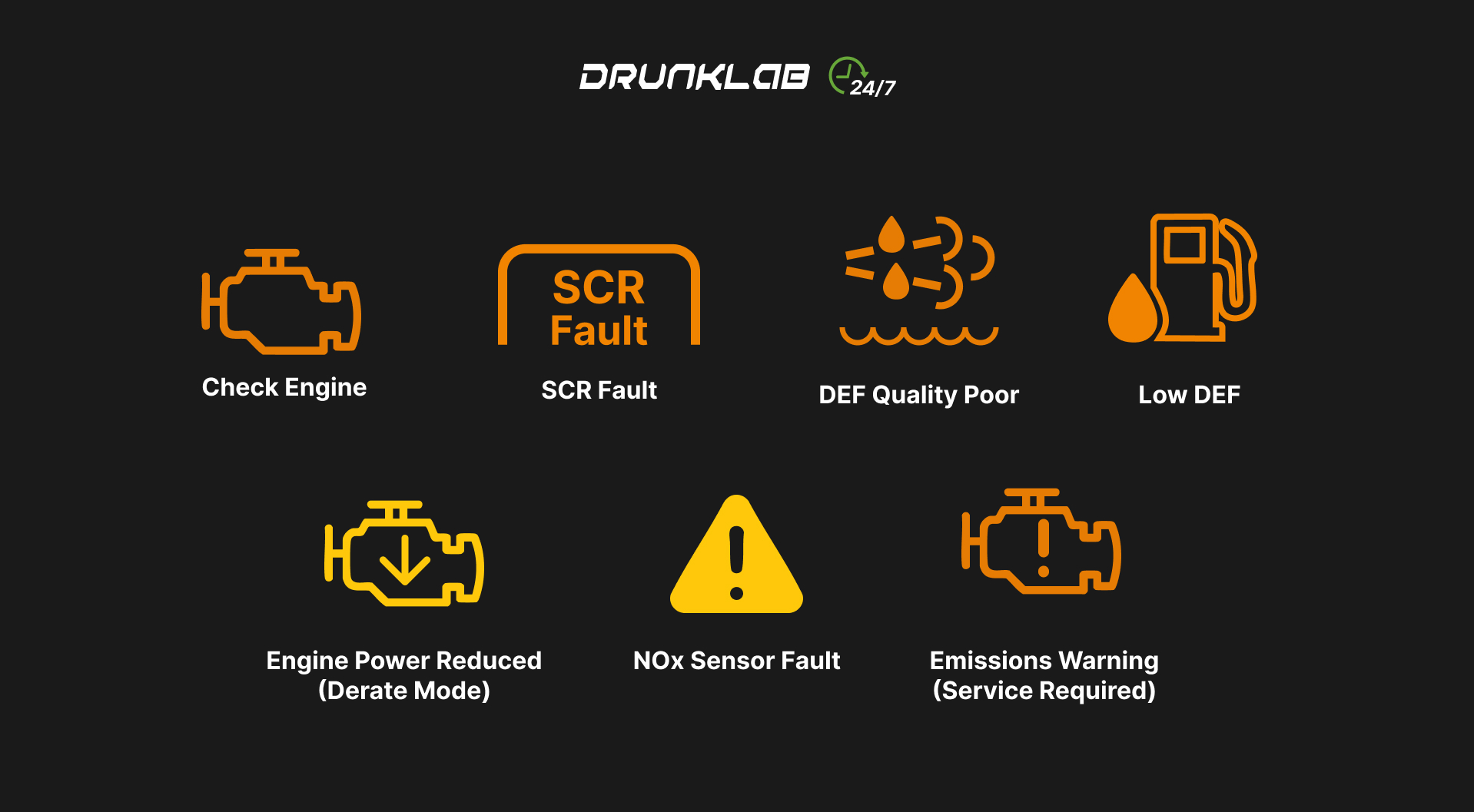

Errors and Causes of SCR Malfunctions

The most common problems during the operation of trucks arise due to failures in the SCR system. In the event of such a malfunction, vehicle operation can be significantly hindered, as the electronic control unit (ECU) activates emergency mode, reducing engine power (torque) to 40%. This mode is activated when there are active fault codes in the SCR system, indicating problems with the exhaust gas aftertreatment system (see Figure 3).

When emergency mode is activated, the ECU reduces the amount of fuel injected into the cylinders and decreases the volume of exhaust gases, thereby protecting the environment from pollution. However, this severely limits the vehicle’s functionality, making it unsuitable for further operation, especially during long-haul transports.

Possible Indicators of SCR System Malfunction on the Dashboard

(Figure 3)

The most frequent cause of exhaust aftertreatment system failure is the use of low-quality AdBlue fluid. Such fluid may contain various impurities, including petroleum products (diesel fuel, oils). The presence of such impurities almost instantly leads to the failure of key SCR system components, such as:

- AdBlue supply pump.

- Dosing valve (injector).

- Catalytic system elements.

Failure of the SCR system results in the engine not working, as the electronics will block even its start. A similar lock is triggered when the AdBlue tank is empty: the vehicle can travel a few dozen more kilometers, but restarting the engine will be blocked by the ECU.

Repair or Disabling SCR: Solution Options

The SCR system is complex to repair and expensive to maintain. Equipment owners facing malfunctions often find themselves choosing between repairing the system or completely disabling it. There are three main approaches to solving this problem:

1. Contacting a Service Center

This option guarantees that your vehicle will comply with EURO and TIER standards after the repair. However, the cost of services can be quite high, considering the complexity and expense of SCR components.

2. ECU Reprogramming

Disabling the system through ECU reprogramming is relatively simple for a specialist, but it is important to consider that any software update for the vehicle resets such reprogramming, and the SCR system activates again. Additionally, modified software can create problems when selling the truck.

3. Installing an AdBlue Emulator

This method is often considered the simplest. The AdBlue emulator is safe to use, easy to install, and can be disabled or completely removed in minutes.

Advantages of Disabling SCR and AdBlue

Arguments For:

- Significant reduction in maintenance costs and decrease in the likelihood of breakdowns related to the SCR system.

- Increased engine performance by removing restrictions imposed by the SCR system, leading to higher output power and optimized fuel combustion.

- Extended service life of engine components due to reduced thermal load on some exhaust system elements, also potentially increasing their durability and reducing the risk of corrosion in elements.

Arguments Against:

- Some increase in nitrogen oxide emissions.

These advantages make disabling SCR an attractive option for many truck and construction equipment owners seeking to minimize operating costs and increase the reliability of their vehicles.

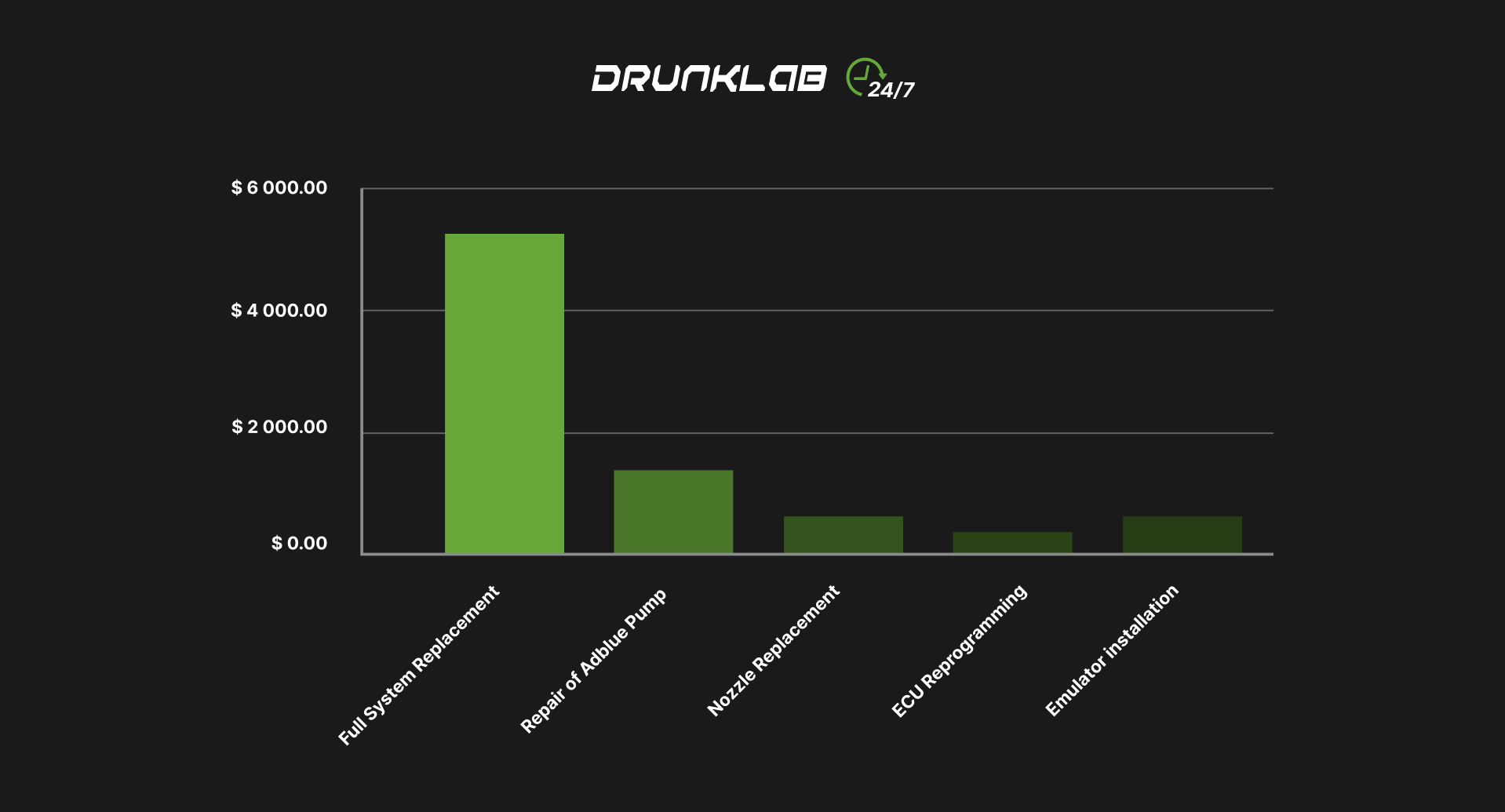

Cost Comparison: Repair or Disabling SCR

Let’s consider approximate costs for repairing the SCR system compared to disabling it to help equipment owners make the optimal decision, These figures may vary depending on the region, brand and model of the truck, as well as the specific type of malfunction.

Comparative Cost Diagram for the SCR System

(Figure 4)

As seen from the diagram, full replacement of the SCR system is the most expensive solution. Repairing individual components can also be a significant expense item. At the same time, options such as ECU reprogramming or installing an AdBlue emulator offer a more economical solution, although with their own nuances, which we mentioned earlier.

Conclusion and Recommendations

In the modern world, for maintaining an environmentally friendly exhaust from a diesel engine, the SCR system essentially has no alternative, and the use of AdBlue fluid will remain relevant for a long time. Nevertheless, the decision to disable SCR always rests with the vehicle owner.

When deciding on disabling or repairing the SCR system, as well as for any questions related to environmental systems and settings for your truck equipment, you can contact specialists.

The Drunklab company offers 24/7 free consultation on all aspects of removing SCR + AdBlue systems, disabling other environmental systems, and other settings.

We look forward to cooperating with you!