Exploring EGR in Diesel Trucks: Purpose, Types, and Malfunction Management

Introduction

This article contains trucks Exhaust Gas Recirculation (EGR) system detailed examinationю. We will explore its purpose, design, various valve types, features of high- and low-pressure systems, and combined solutions. Special attention will be given to signs of malfunctions, diagnostic methods, and the critical pros and cons of disabling the EGR system.

EGR System Purpose

The technology first appeared in North American gasoline engines during the 1970s, soon spreading to diesel powertrains in the 1990s, especially heavy-duty trucks. By advancing the timing of combustion and lowering peak cylinder temperatures, the system achieves a significant reduction in NOx without adding a secondary after-treatment stage. By diluting the intake air-fuel mixture, the valve decreases the oxygen content, cools the combustion flame, and can cut NOx emissions by up to 70%.

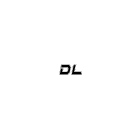

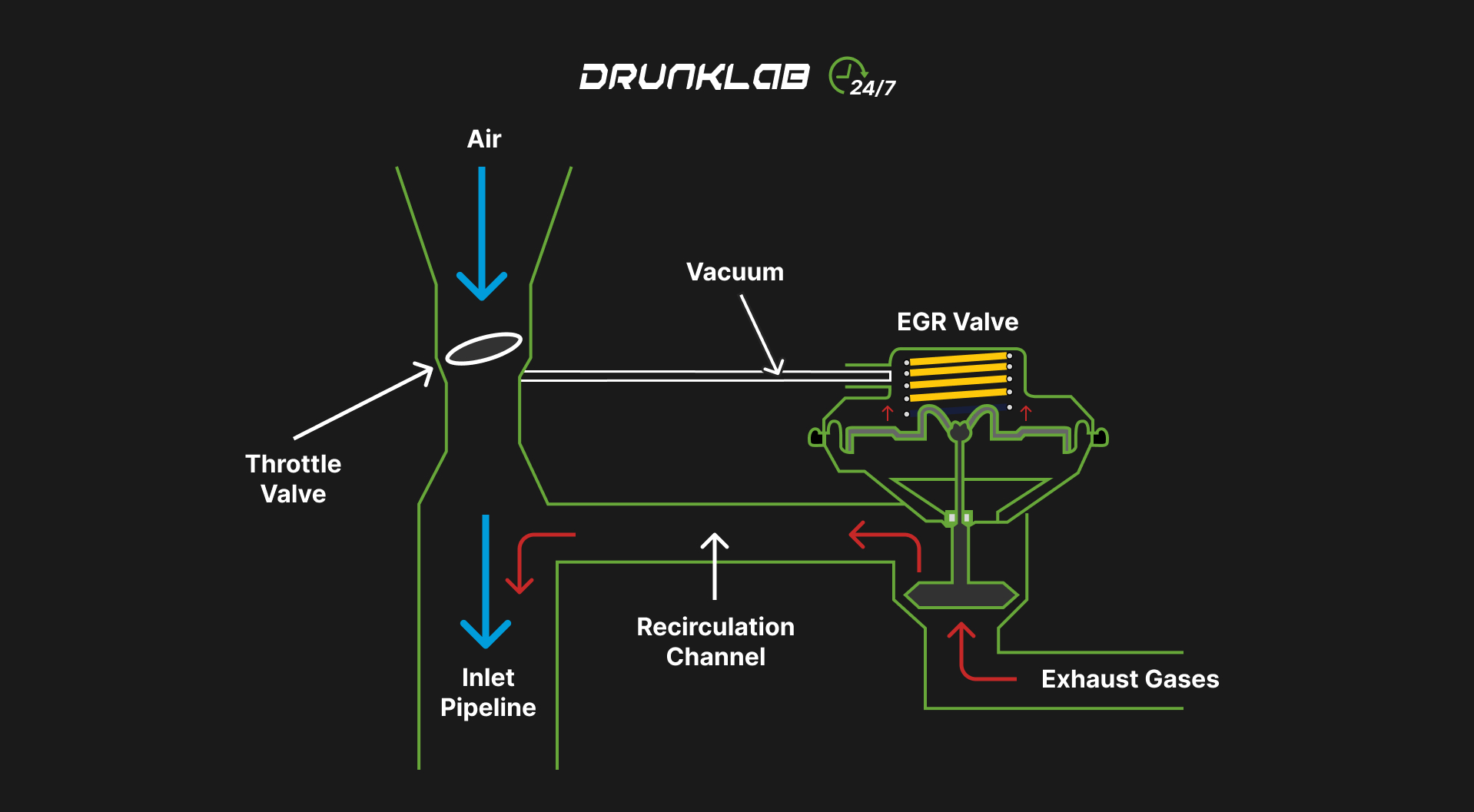

EGR Valve General Diagram

(Figure 1)

The EGR valve fine-tunes the oxygen level in the charge air whenever the engine runs, depending on the current load and thermal state:

- Initial start and warm-up

- Partial or low load

- Stable RPM

- High or low atmospheric pressure

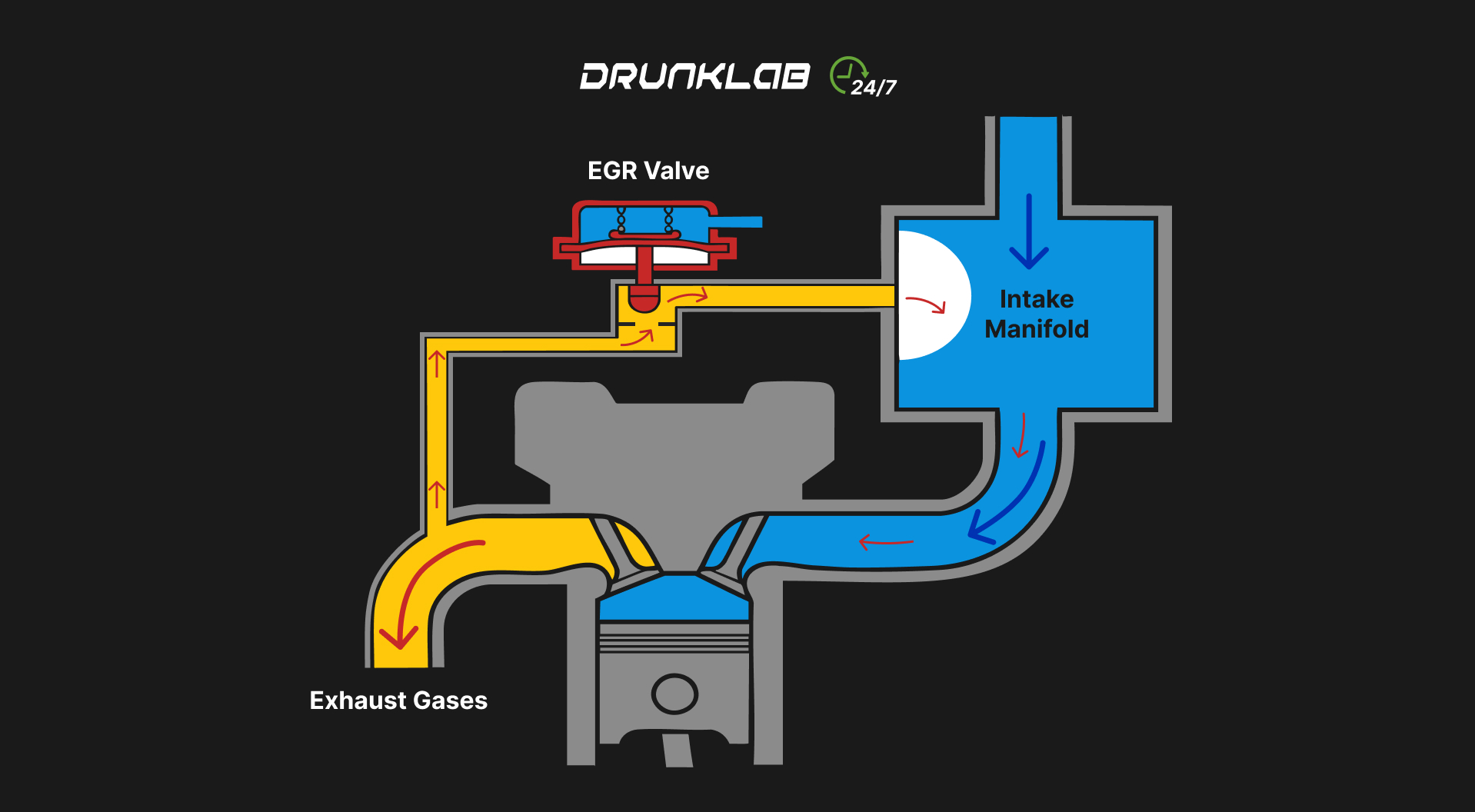

EGR Valve Design & Operating Principle

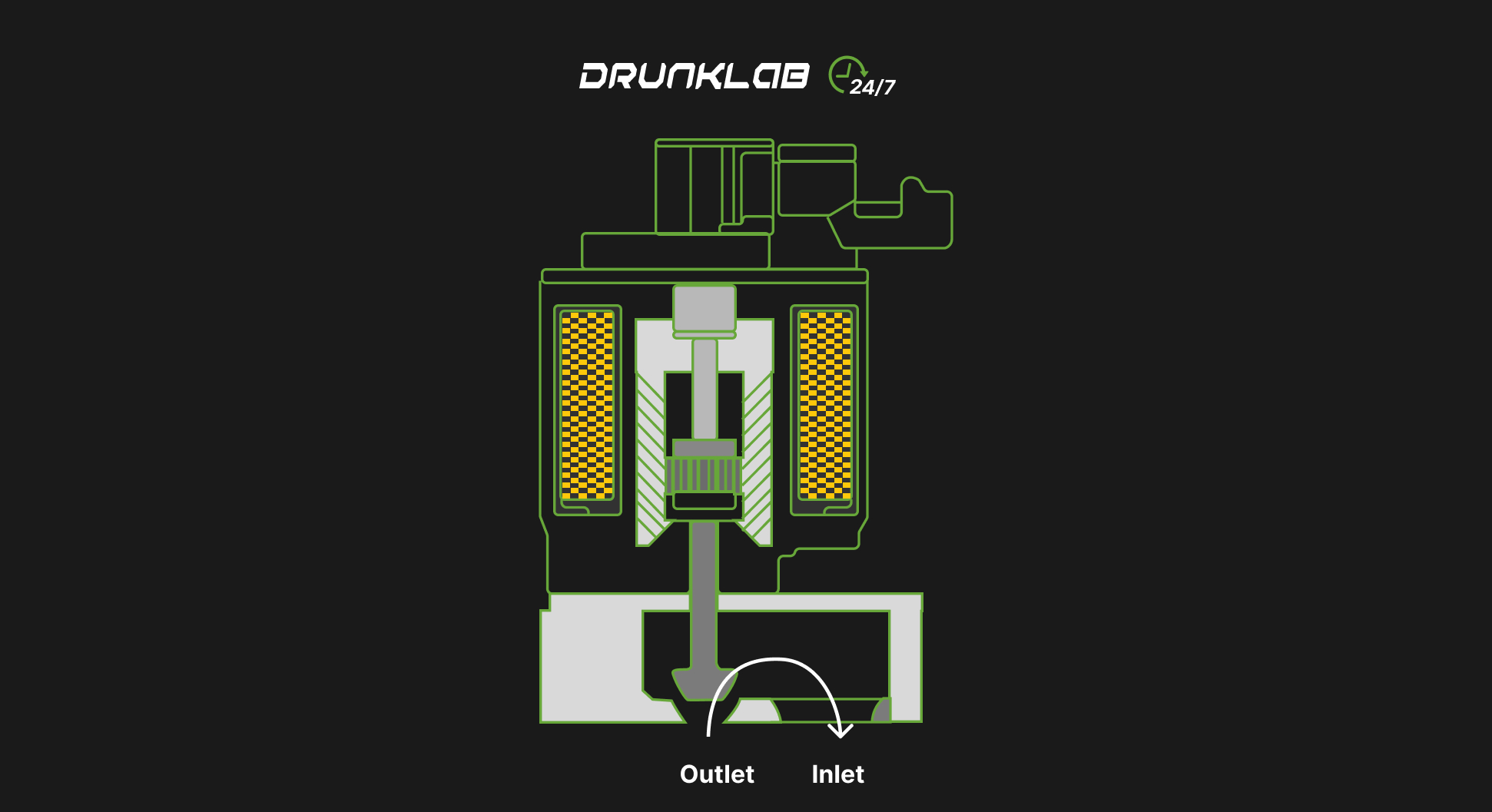

The EGR valve is a housing containing a stem that opens or closes an aperture for the passage of exhaust gases. The valve is attached to the stem, which operates either pneumatically, driven by vacuum (see Figure 2), or electrically, controlled by the Electronic Control Unit (ECU).

Pneumatic EGR Valve General Design

(Figure 2)

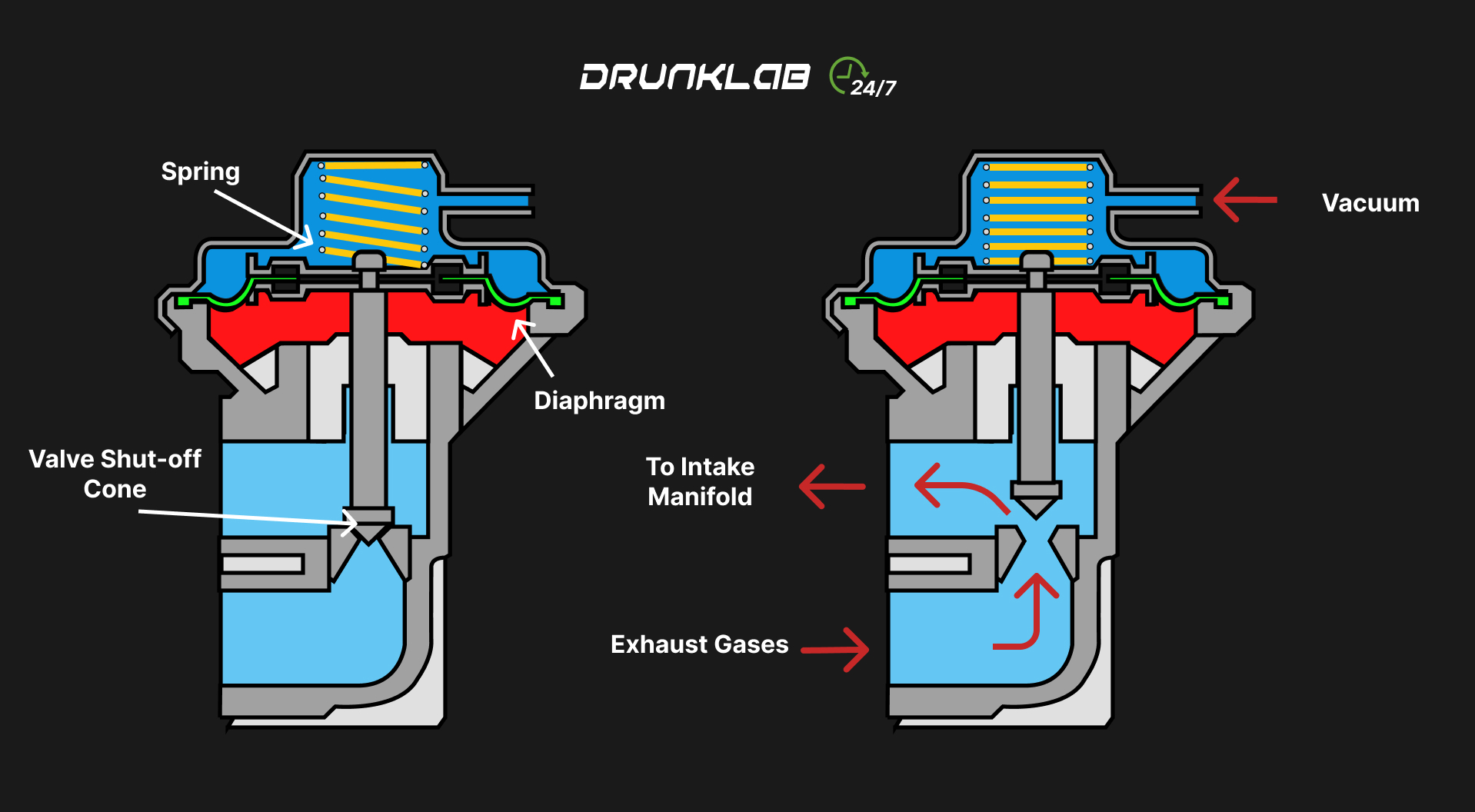

EGR Valve Types by Cooling Method

- Without Cooling

Simple valves where exhaust gases enter the intake manifold without additional cooling. Found in older trucks.

Advantage: Simple design.

Disadvantage: Relatively low performance against NOx emissions. - With Cooling

Modern trucks are equipped with coolers that lower the temperature of recirculated gases using antifreeze or air (see Figure 3).

Advantage: Significant reduction in emissions.

Disadvantage: System complexity and susceptibility to contamination.

EGR Valve with Cooler

(Figure 3)

- With Bypass Valve

Used in cooled systems. The bypass design reroutes exhaust around the intercooler when the engine is cold so the system warms more quickly, lowering unburned-fuel emissions and improving operational efficiency before reaching normal temperatures.

Advantage: Optimizes engine operation during cold starts.

Disadvantage: Extra parts make the system more complicated to manage.

By Position & Design

- Internal EGR Systems

The loop is built in using cam or variable timing, so there’s no stand-alone actuator. This approach is relatively rare in heavy trucks.

Advantages: No separate valve, high reliability.

Disadvantages: Complex tuning, limited application. - External EGR Valves

Classic design where the valve connects the exhaust and intake manifolds via a separate channel. The most common type in trucks.

Advantages: Easy maintenance and replacement.

Disadvantages: Susceptibility to soot buildup in channels.

EGR Valve Control Types

- Pneumatic (Vacuum)

Mainly regarded as obsolete. Intake manifold vacuum moves the valve, with a differential pressure sensor providing limiting feedback (see Figure 4).

Advantages: Simplicity, low cost.

Disadvantages: Less precise control, sensitivity to contamination.

Pneumatic EGR Valve

(Figure 4)

- Electronic EGR

The Most popular today. The kind of valve is actuated by a solenoid or stepper motor, controlled by the ECU based on sensor data.

Advantages: Precise gas metering, adaptability.

Disadvantages: Complex design, high replacement cost.

Electronic EGR Valve

(Figure 5)

Regardless of design, all EGR valves operate on the same principle. The difference lies only in the method of actuating the sealing element.

Types of Diesel Engine Recirculation Systems

- High-Pressure EGR Valve (HP-EGR)

Used in Euro-4 engines, where NOx emissions must not exceed 0.25 g/km. The system includes a pneumomechanical or electrically driven EGR valve and pipelines. Vacuum at the exhaust manifold inlet is created by a vacuum pump. The intensity of exhaust gas recirculation depends on engine operating mode and the pressure difference between intake and exhaust. - Low-Pressure EGR Valve (LP-EGR)

Complies with Euro-5 standards (NOx ≤ 0.18 g/km). Exhaust gases pass through a particulate filter for cleaning, then to a cooler for cooling, after which the EGR valve controls their dosage before entering the exhaust manifold. - Combined Recirculation EGR Valve

To meet Euro-6 standards (NOx ≤ 0.08 g/km), engines use a combined exhaust gas recirculation system. Its design includes two separate pipelines: low and high pressure. The operating cycle resembles LP-EGR, but in certain engine modes, the high-pressure circuit is activated to supply additional uncooled gases.

Signs of EGR Malfunction

Carbon buildup is the main reason why EGR valves fail, which causes them to jam. Watch the following signs in your truck:

- “Check Engine” light on for no reason.

- Reduced engine power, hesitation.

- Rough engine idling.

- Jerking during sudden acceleration.

- Increased fuel consumption.

- Detonation, knocking, or clicking in the engine.

Causes and Consequences of EGR Failure

Causes of Malfunction:

- Soot and deposit buildup on components.

- Use of low-quality fuel.

- Incomplete fuel combustion.

- Insufficient crankcase ventilation.

- Malfunction of vacuum or digital pump.

- EGR valve burnout.

- Clogged pipelines.

- Electronic control system failures.

- Manufacturing defects.

Consequences of Failure:

Running a defective EGR valve for an extended period has serious ramifications: Excessive wear of the cylinder-piston assembly and the turbo will generate oil to leak past the seals, leading to sludge buildup and possible valve stem sticking.

Erratic sensor readings will skew the ECU’s corrective responses, pushing the valve to behave incorrectly. The engine may also tolerate higher fuel quantities when the EGR flow is miscalibrated, pushing fuel economy downward.

EGR System Diagnosis & Repair

- Visual Inspection

Inspect the pipelines and connections for deformations, mechanical defects, damaged electrical connectors, and carbon buildup. - In-Depth Service Diagnosis

Use the oscilloscope, multimeter, and other equipment for exact diagnosis. Specialists check EGR components, wire resistance, intake pressure, air consumption, and ECU signal accuracy. - Computer Diagnostics

The most precise method. Computer diagnostics can confirm that engine issues stem from an EGR component failure, such as low exhaust gas return intensity or intake system leaks. - Repair and Replacement

Due to low repairability, most EGR components require replacement. The valve itself can often be restored by cleaning. New components may need to be programmed into the ECU using a diagnostic scanner after the replacement.

EGR Delete: Pros & Cons

Arguments for Disabling EGR:

- Enhanced engine efficiency by minimizing cylinder pollution caused by unburned combustion residues.

- Reduced carbon buildup in the intake system.

- Lower engine temperature.

- Improved throttle response.

- Reduced average fuel consumption.

- Simplified engine system design and maintenance.

- Avoidance of labor-intensive cleaning and replacement.

- Long-term savings on parts costs.

Arguments Against Disabling EGR:

- Increased NOx emissions.

EGR Delete Methods

- Mechanical Deletion: For pneumatic EGR, disconnect and plug the vacuum hose. For cooled systems, install plugs on pipelines or loop the cooling system.

- Software Deletion (ECU Reprogramming): It is required for pneumo-electric and electric EGR systems. That prevents “Check Engine” errors and emergency mode activation.

The decision to disable EGR is up to the vehicle owner. However, it’s critical to understand all potential consequences and entrust this work to professionals to avoid negative impacts on other vehicle systems.

Drunklab’s support team is always ready to provide free 24/7 consultations on all matters related to EGR system removal, disabling environmental systems, and other settings for your truck.

We look forward to cooperating with you!