Diesel Particulate Filter: Operation, Environmental Impact, and Modification Choices

Introduction

The modern world and its development trends, combined with changing environmental factors, create increasingly strict requirements for freight transport and construction equipment, which involve minimizing emissions of harmful substances into the atmosphere to ensure environmental safety standards. One such component is a diesel particulate filter, more commonly known by its international abbreviation as DPF (Diesel Particulate Filter).

Purpose, Design & Operating Principle of DPF

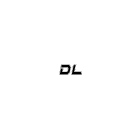

The DPF system captures soot and carbon black (see Figure 1), ensuring environmental safety, as exhaust gases contain particles formed from complex carbon compounds with various components.

DPF Operating Principle of the Particulate Filter

(Figure 1)

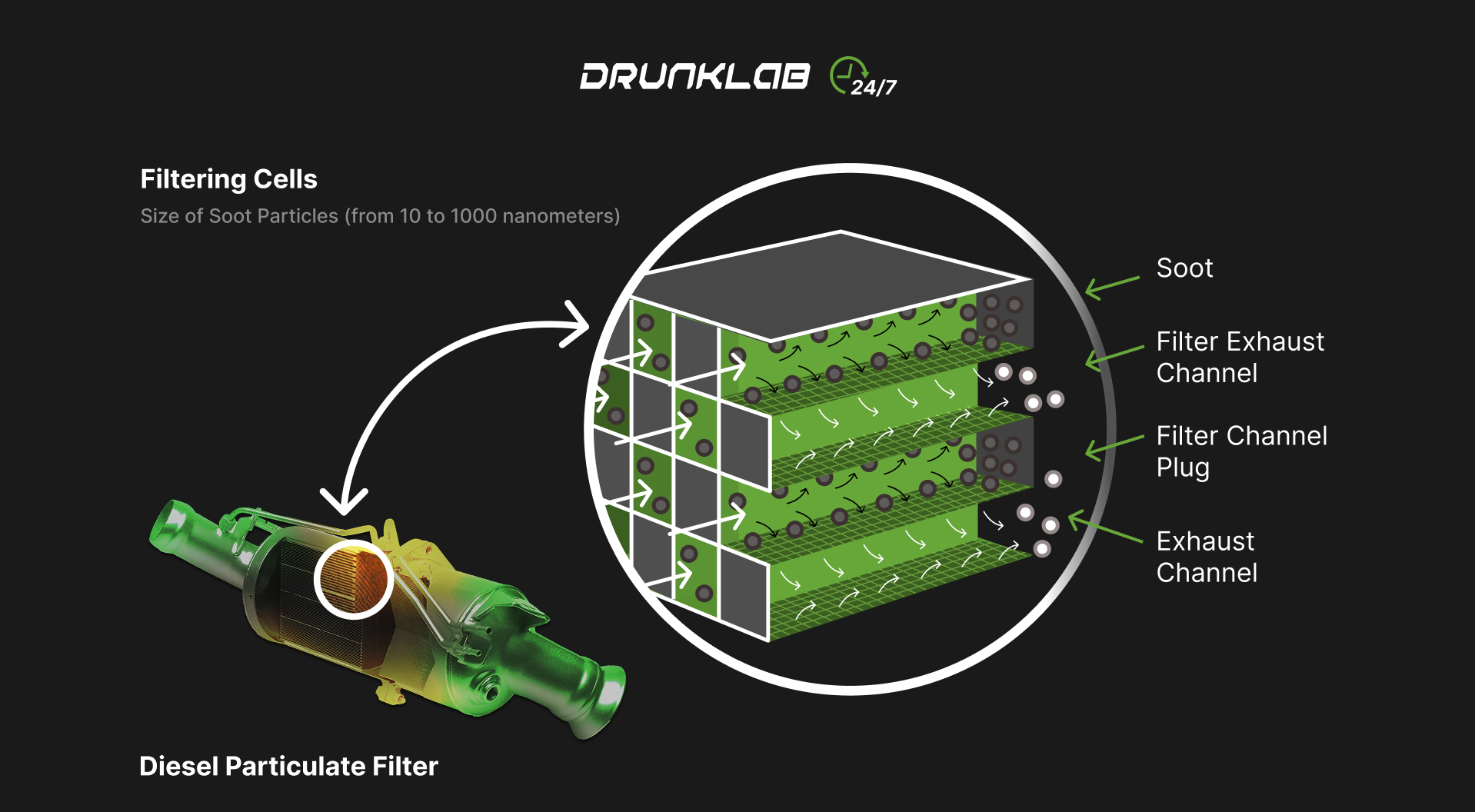

The DPF is installed in the exhaust tract after the catalyst (DOC – Diesel Oxidation Catalyst) and is often housed in a common body (see Figure 2). Depending on the design and operating principle, DPF filters are divided into passive and active.

General Schematic of Ecology Systems

(Figure 2)

A passive DPF filter is a sealed steel cylindrical unit with a ceramic cell structure inside. The cell surface is coated with platinum. The porous cartridge is pierced with narrow channels (quadrangular or octagonal in cross-section), partially open on one side and closed on the other. Platinum initiates a chemical reaction that decomposes solid elements without forming new ones, ensuring high cleaning efficiency.

The operating principle of an active DPF filter is also based on the chemical interaction of pollutants with the cell coating. However, the required soot combustion exhaust temperature is increased by the electronic control unit (ECU).

Passive & Active DPF Comparison

| Characteristics | Passive DPF | Active DPF |

| Regeneration Temperature | 482–662°F (250–350°C) | 1022–1112°F (550–600°C) |

| Oxidizer | Nitrogen Dioxide (NO₂) | Oxygen (O₂) |

| Main Reaction | NO₂ + C → NO + CO, CO → CO₂ | C + O₂ → CO₂ |

| Operating Conditions | High Load, Track | Any, Including Urban Cycle |

| Fuel Consumption | Mininmal | Increased due to to Fuel Injection |

| System Complexity | Simple (DOC+DPF) | More Complex (add. Fuel, Heating) |

Exhaust gases enter the inlet ports, from which exit is possible only through the porous silicon carbide structure (ceramic). Interacting with platinum, solid particles burn, forming carbon dioxide. Exhaust gases are freely discharged into the atmosphere through the filter, while solid soot particles are retained inside. The state of the exhaust gases is monitored by sensors installed in the device, recording exhaust indicators.

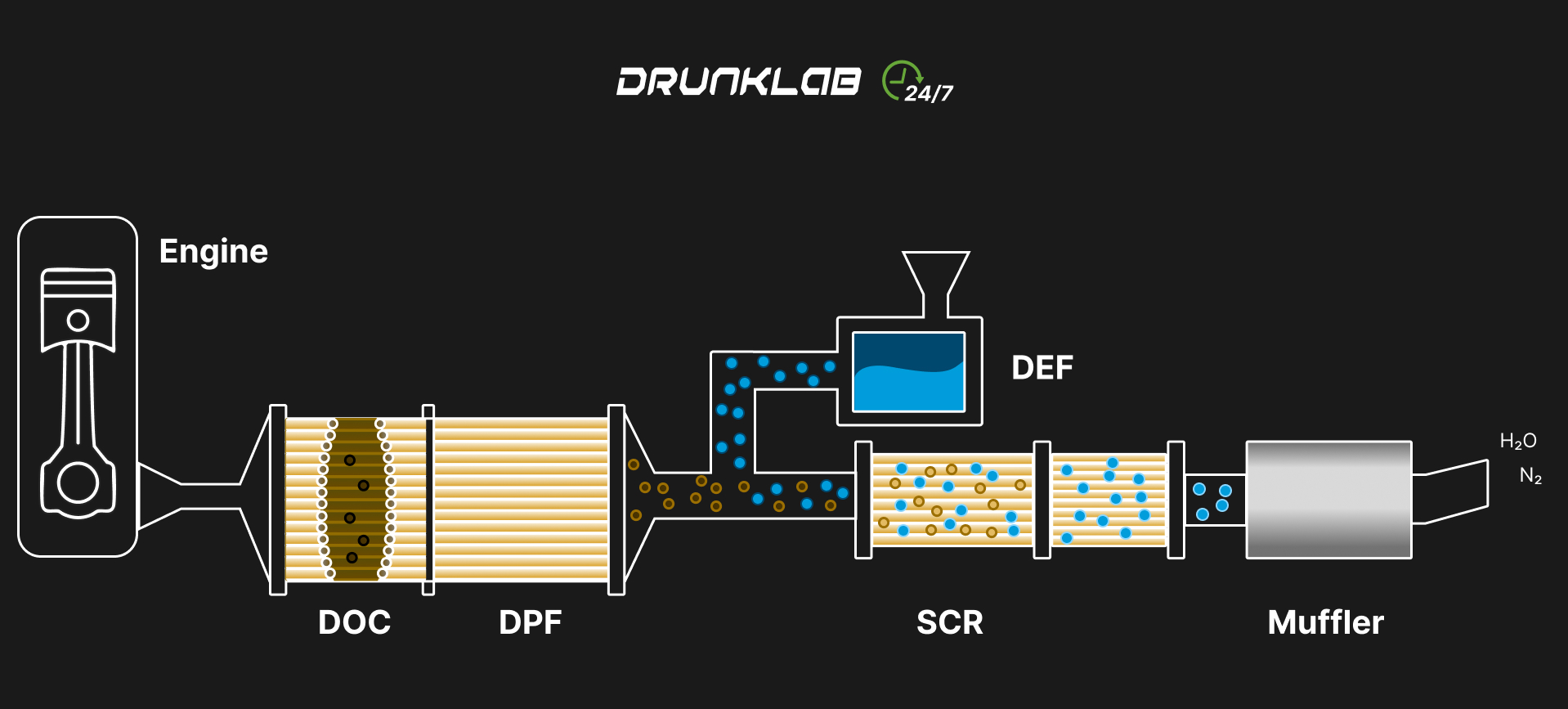

Through connectors on the housing, temperature sensors, particulate filter sensors, catalyst sensors, and differential pressure sensors are connected to the DPF filter, installed before and after the filter (see Figure 3)

Sensor Layout Diagram

(Figure 3)

DPF Regeneration Process

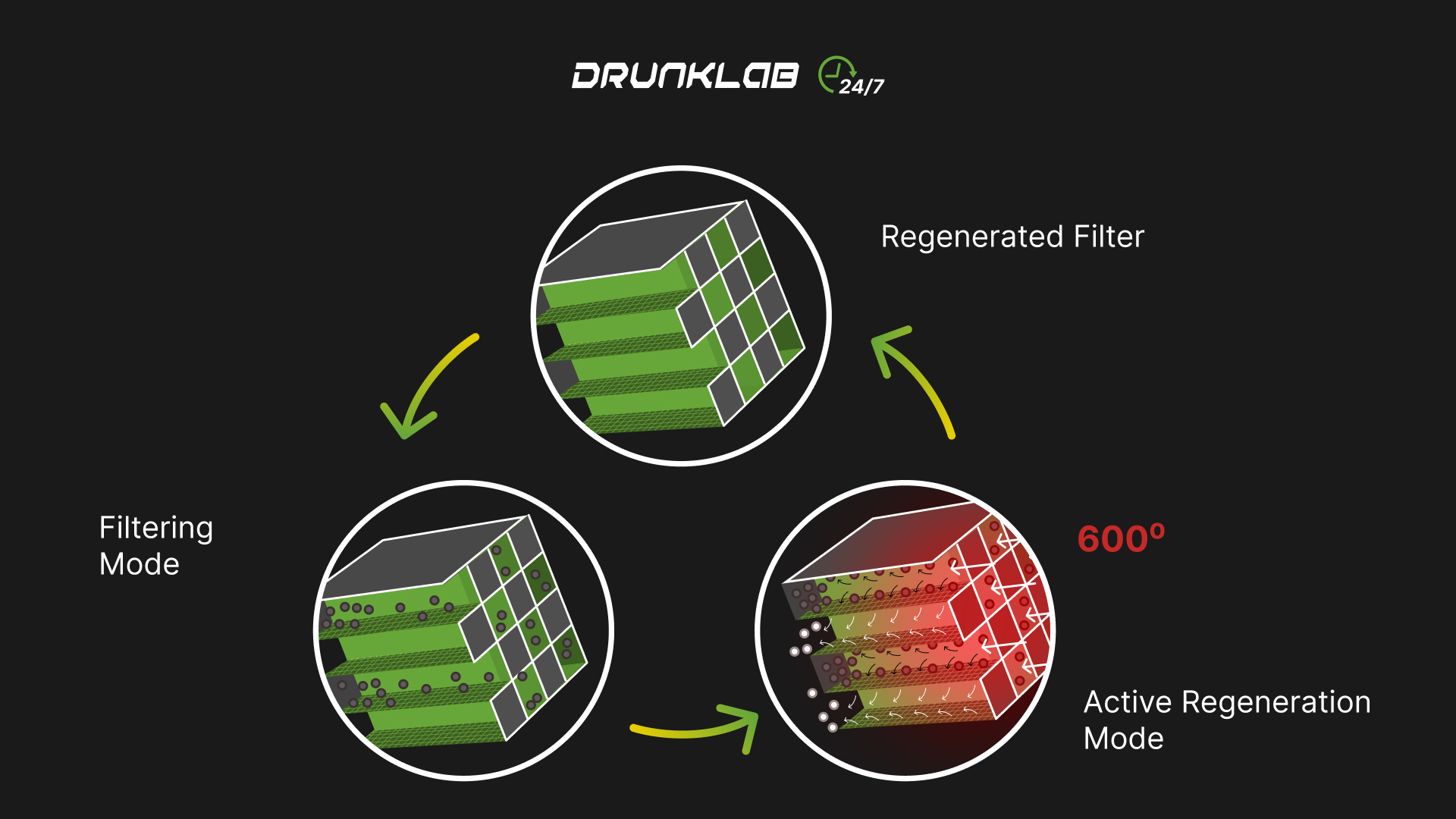

The DPF is a self-regenerating unit, but to initiate the regeneration process, the appropriate engine operating mode must be ensured. It occurs continuously during engine operation and is possible until the DPF is completely clogged. Then, when the self-cleaning mechanism is activated, soot deposits burn out (see Figure 4). картинка?

During regeneration in the particulate filter, nitrogen dioxide (NO₂) is formed as a result of the reaction of oxygen (O₂) with nitrogen oxide (NO). This substance, upon contact with soot (C), releases nitrogen oxide (NO) and carbon monoxide (CO) again. In the subsequent oxidative reaction, these components are converted into nitrogen dioxide (NO₂) and carbon dioxide (CO₂).

DPF Regeneration

(Figure 4)

There are 3 types of regeneration: passive, active, and forced.

Passive regeneration occurs automatically during normal engine operation, without additional intervention (see Figure 5). The process depends on the chemical reaction between nitrogen dioxide (NO₂) and soot (carbon, C), which takes place at relatively low temperatures (250–350°C). Nitrogen dioxide (NO₂) oxidizes the soot, converting it into carbon monoxide (CO) and nitrogen oxide (NO), which are then oxidized to carbon dioxide (CO₂) and NO₂.

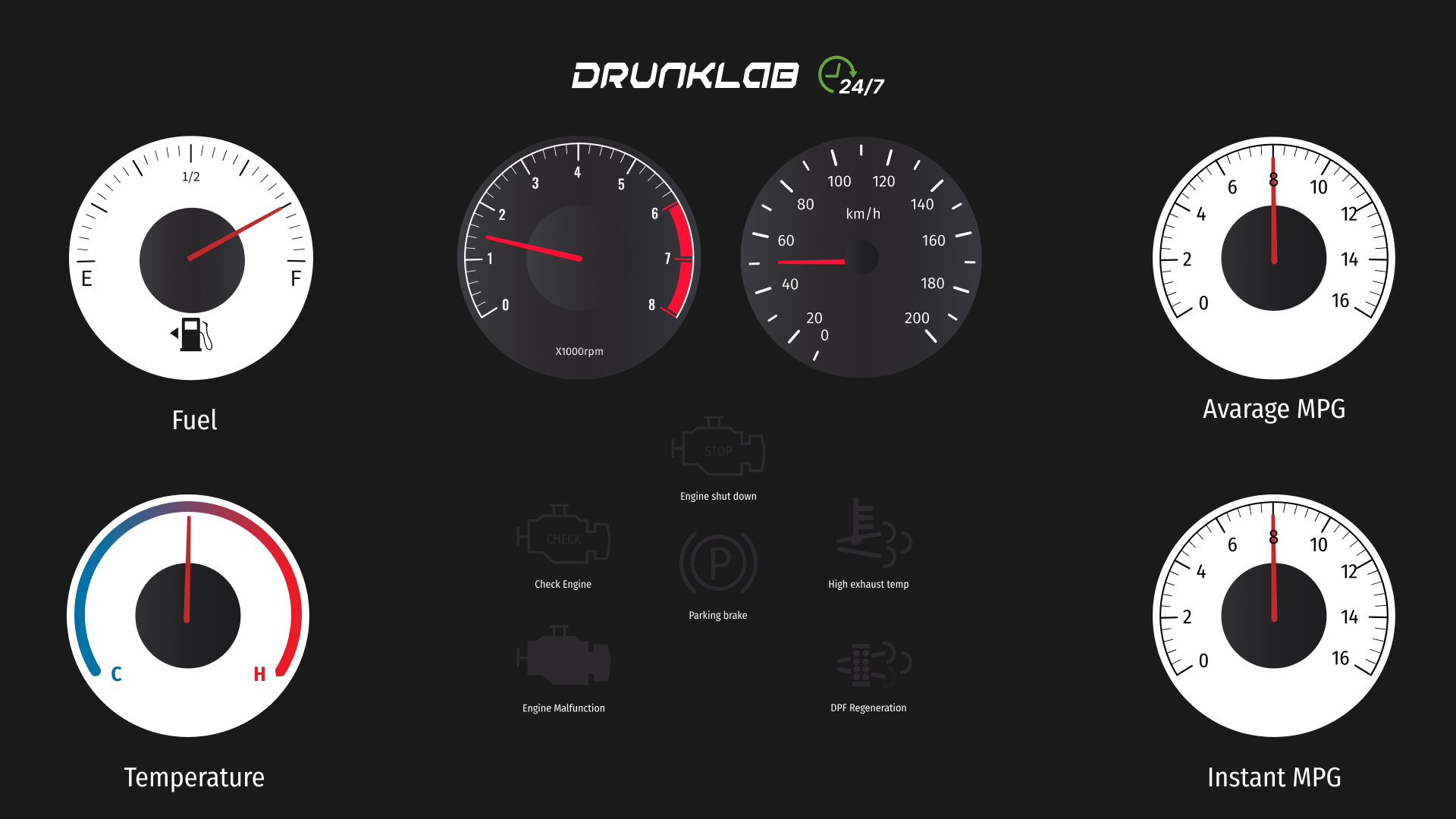

Possible Dashboard State During Passive Regeneration

(Figure 5)

Active regeneration is initiated by the engine control system (ECU) (see Figure 6), when the particulate filter fills with soot, and the exhaust gas temperature is insufficient for passive regeneration. The process involves increasing the exhaust gas temperature (usually to 550–600°C) to burn the soot (C) and form carbon dioxide (CO₂).

The temperature is increased by injecting additional fuel into the cylinders or directly into the exhaust system, or by using electric heaters (less commonly).

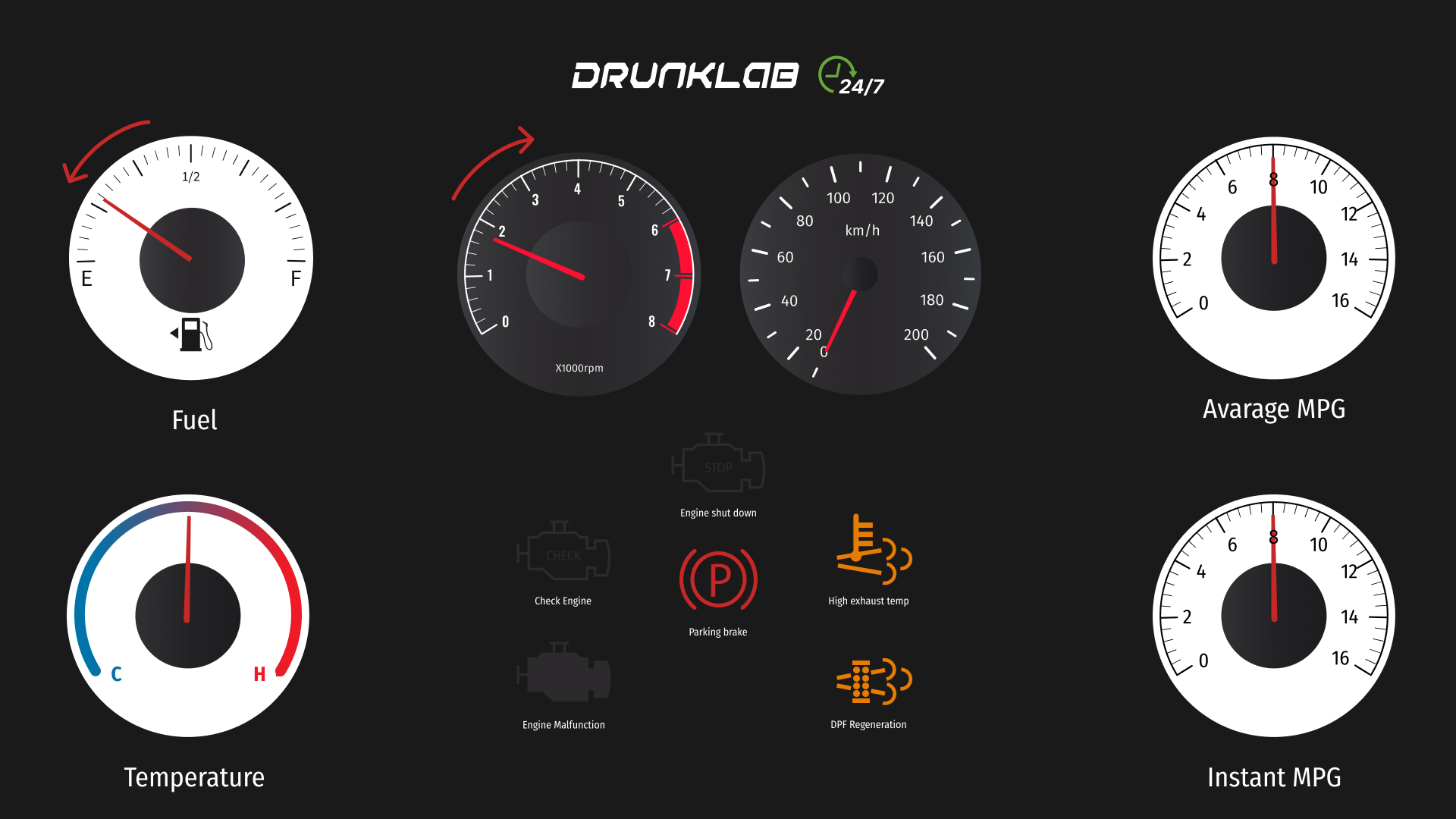

Possible Dashboard State During Active Regeneration

(Figure 6)

Forced regeneration is a type of active regeneration that is performed when the truck is stopped and the engine is idling (about 1 hour). However, since metallic ash does not burn out and continues to accumulate in the particulate filter, over time, with significant clogging of the particulate filter (up to 80%), regeneration becomes ineffective or impossible, requiring DPF cleaning at a service station or its replacement.

Possible Dashboard State During Forced Regeneration

(Figure 7)

It is strictly not recommended to shut off the engine and interrupt the initiated regeneration. It is necessary to wait for the process to complete. Usually, it takes 15 minutes; otherwise, your ECU will record that regeneration did not occur.

DPF Maintenance & Replacement

When the particulate filter indicator lights up on the truck’s dashboard (see Figure 8), it means the DPF is clogged by 50-70%.

For active self-cleaning, it is necessary to take a highway trip at a speed of 70-100 km/h for 15-30 minutes.

If both the DPF indicator and the “check engine” light up simultaneously, service regeneration is required, as it is clogged to a critical level and replacement may be necessary. (see Figure 8).

(Figure 8)

The cost of replacing and maintaining a particulate filter can vary widely, depending on your truck model, the location and accessibility of the filter, its type, the cost of work at the service center, and other regional factors.

The following table provides approximate price ranges for the DPF maintenance, replacement, and delete for Volvo, Renault, and Mack trucks, as commonly used in the freight transportation industry. It is important to note that when replacing, both original filters and compatible analogs can be used. Their cost may differ from originals, as may the feasibility of installation in each specific case.

| Type of Service | Truck Brand | ||

| Volvo | Renault | Mack | |

| DPF Basic Cleaning without additional service | 300-1000$ | 500-1000$ | 200-700$ |

| DPF Replacement | 1400-10000$ and more | 2500-10000$ and more | 1400-10000$ and more |

| DPF Delete + ECU Tuning (may include EGR & SCR Delete) | 1250-3200$ | 1200-3000$ | 1250-3200$ |

DPF Removal Pros & Cons

DPF modification or deletion from any vehicle can change the engine’s operation, and below we will consider all the pros and cons if you decide to execute this operation.

Deletion can be done in various ways, but the most common is mechanical removal. It can be done independently if you have the necessary equipment and sufficient experience.

However, it is better to consult qualified specialists who deal with this on a regular basis, as simple deletion the DPF without reprogramming can lead to the following negative consequences:

- Increased fuel consumption;

- Worsening of the vehicle’s environmental performance and exhaust odor;

- Vehicle warranty loss;

- Unstable engine operation due to the installation of non-original or low-quality parts.

And if you still decide to delete DPF, then immediately after that, you should reprogram the ECU so that your truck continues to operate correctly.

Main Pros & Cons of DPF Removal:

- Increased engine power due to increased oxygen flow into the cylinders. This leads to more efficient fuel combustion and increased power.

- Reduced maintenance costs, due to the absence of the need for regular regeneration, cleaning, and ultimately, expensive filter replacement. This leads to significant savings on maintenance in the long term.

- Reduced vehicle downtime due to DPF issues and the time to resolve them.

- Increased emissions level into the atmosphere;

- Crankcase ventilation, catalyst, and turbocharger possible problems;

- Violating environmental standards fines if discovered.

Conclusion

In this article, we have examined in detail the diesel particulate filter (DPF) – its design, operating principle, regeneration mechanisms, as well as maintenance issues and potential consequences of deletion. We evaluated the importance of using DPF to ensure the environmental safety of freight transport and analyzed the arguments “for” and “against” modifying this system.

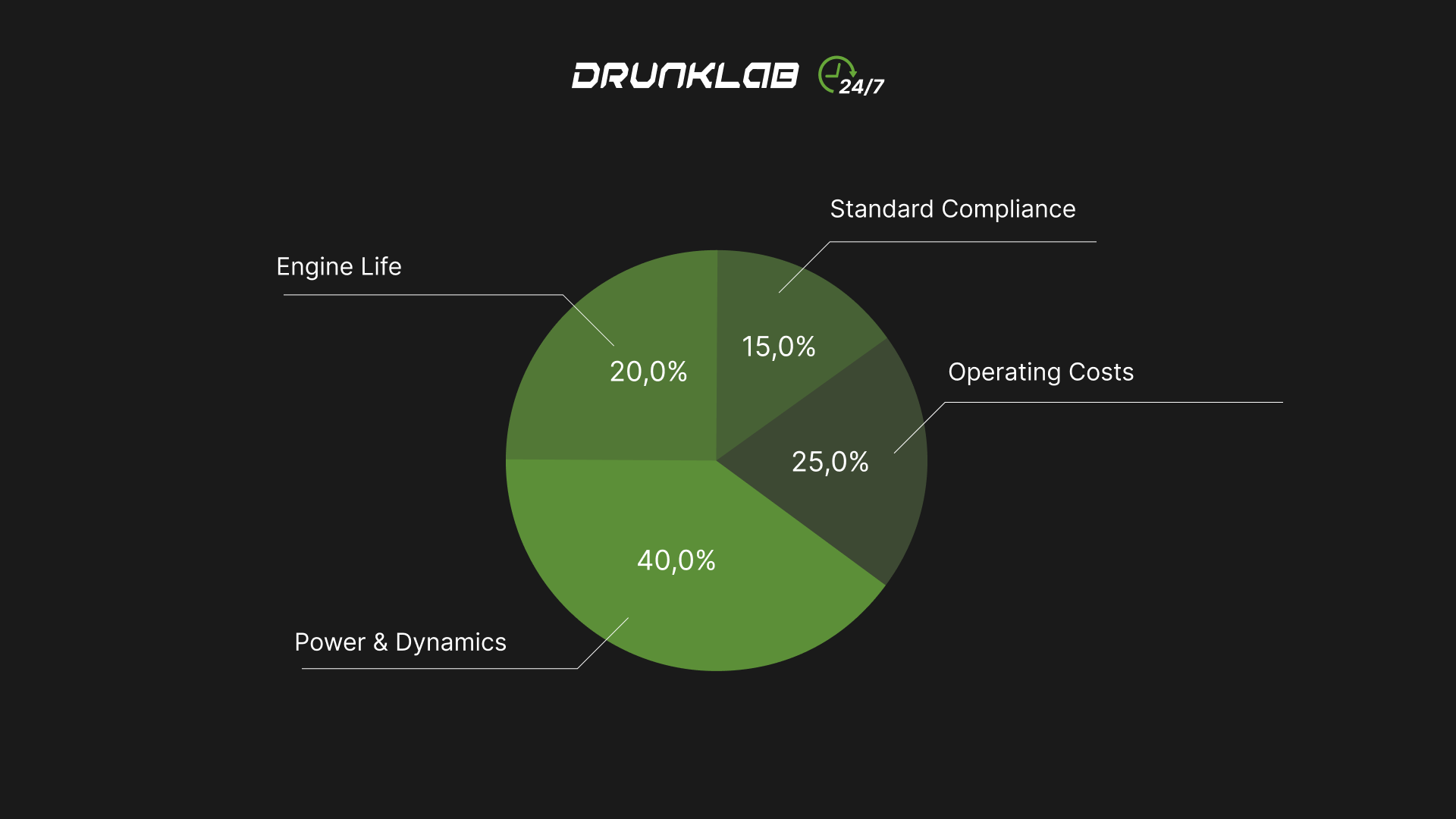

Diesel Engine Operation Priority Structure

As the presented diagram shows, the highest priority in operating diesel engines of trucks should be given to issues of performance, operating costs, and the unit service life, without forgetting compliance with environmental standards.

The choice between keeping or removing the DPF is a comprehensive decision that should be based on a thorough analysis of all factors: the vehicle type, its operating conditions, and personal priorities.

The Drunklab support service managers are always ready to provide free consultation 24/7 on all issues related to DPF delete, disabling ecology systems, and other settings for your freight equipment.

We look forward to cooperating!